In order to find the position of the optical table back easily, if

it had to be removed, a 3-point mount consisting of point, groove &

plane, is anchored to the floor. Tooling balls are attached to the

movable table legs. The table can be landed easily on the kinematic

mount as the critical components of the point and the groove are

positioned in easily accessible positions, while the uncritical plane

supports the leg in the rear upstream position (see picture).

The table height is controlled by the 3 DC motor-driven adjustable

legs and the z jacks of the table top. The DC motor positions have to

be adjusted manually with the driver box which allows to control each

of the 3 legs individually. For this purpose the six jacks of the table

top should be placed at there center positions and the table should be

jacked up to the beam height (see section "Optical Bench") and then

levelled (below the adjustable table top). The kinematic mount ensures

that the lateral table positions are within reach of the table top

motors.

The six table top jacks including a 3-point mount as well as passive

sliders allow the table to be positions for 3 translations and three

rotations. The three z-jacks control table height as well as table

pitch and

table roll. The two x-jacks control the x-position

perpendicular to the beam as well as table yaw. Finally the y motor

moves the

table along the beam.

Names and positive directions follow the usual hutch coordinate

system with x pointing towards the storage ring, y along the beam, and

z vertical. Positive rotation directions are determined by the

right-hand rule: if the thumb points in direction of the rotation axis

with orientation determined by the hutch coordinate vectors, the finger

indicate the positive direction.

The Newport X-95 optical bench has to be aligned parallel to the

beam and at the canonic height that leaves a 9 1/2" spacing between the

top of a X-95 clamp and the beam. For this part of the line-up a

suitable pinhole in combination with an ion chamber are used. As soon

as the table has been driven within a couple of mm of correct height

with the DC motors, the line-up pinhole is placed at the upstream jack

position. Motors "xu" and "zu" are scanned to center the pinhole on the

beam.

The the pinhole is placed at the downstream jack positions and now "xd"

and "zd" are centered on the beam. Now the optical bench is parallel to

the beam at the canonic distance.

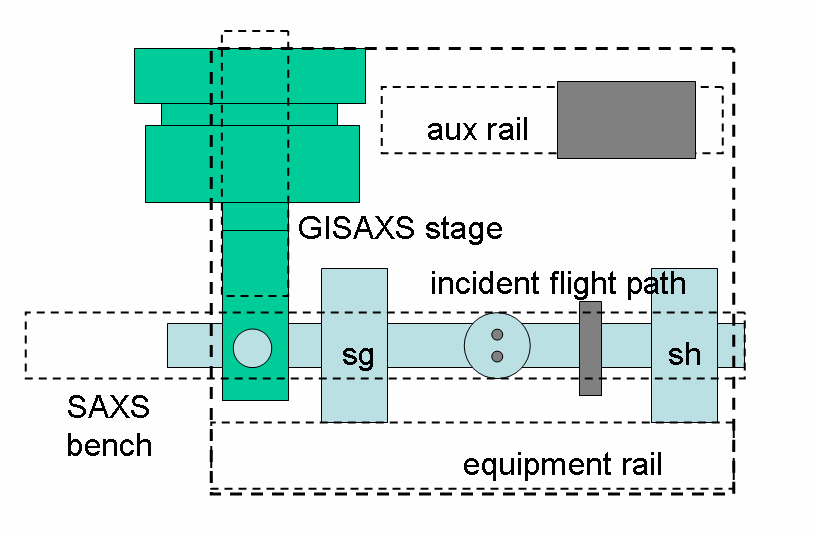

With the optical bench lined up the flight path componts more or

less will just fall into place. The assembly starts from the upstream

end: The beam-defining slits "sh" is connected to the rigid flight path

into the cave by a bellows. It is advisable to leave the screws

mounting the slits to the height adjustment loose until the successive

components are put into place. Next arts are the CCD shutter, the

"Imon" ion chamber, and the guard slits "sg". "sg" and the rigidly

coupled "Imon" chamber are prealigned and "sh" should just yield as

needed. The smallest aperture is defined by "Imon". Finally various

windows can be mounted of the KF-40 tee with the helium inlet.

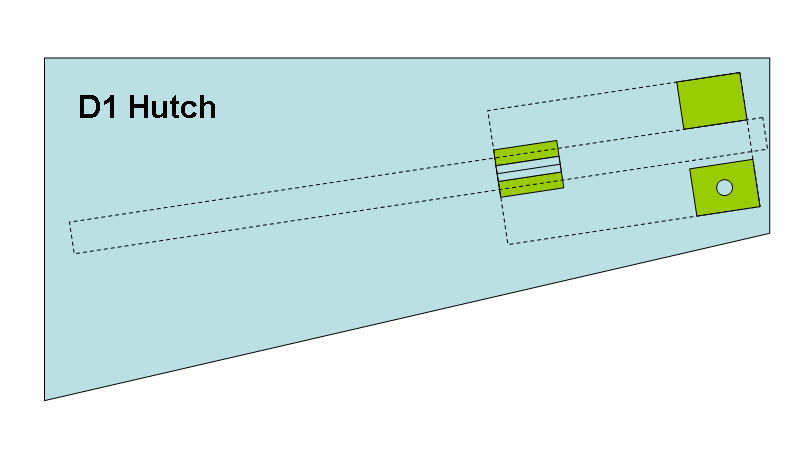

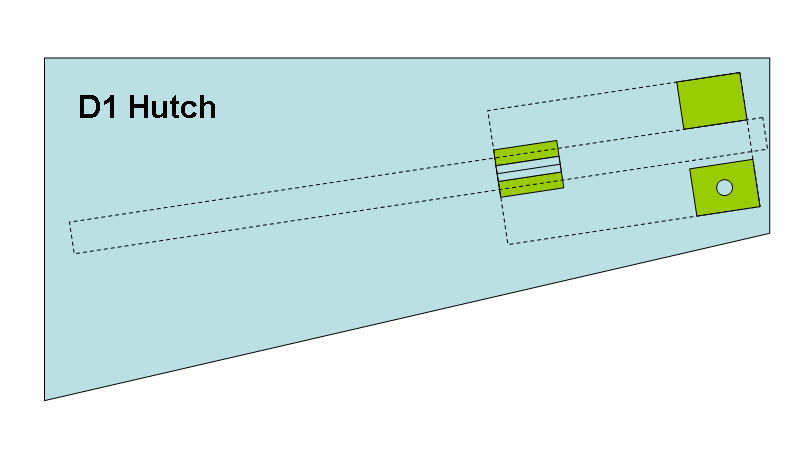

The D1 GISAXS stage is essential to D1 in-house research and many

user experiments. It is mounted on a separate rail perpendicular to the

optical bench at the downstream end of the optical table. Initially the

table "yu" motor needs to be adjusted quite well to provide the correct

spacing between end of the flight path to the stage.

The GISAXS stage can be removed by simple moving it to the rear, out

of the way for most other experinents. When the sample bracket is

removed, there will be ample space for other sample stages on the main

rail, or the incident flight path can be extended past the stage.

Fig. 2. SAXS/GISAXS rail system

The new version of the optical table has

the full six degrees of freedom by allowing independent motion of the

downstream z-jacks. The set of six translations can be transformed into

three translations in x,y,z and three rotations pitch, roll, yaw using

the following relations:

transforms

zd = (zdr +

zdf)/2

xt

= (xu + xd)/2

yt = yt

zt = (zu + zd)/2

pitch

= deg((zd - zu)/LUD)

roll = deg((zdf - zdr)/LRF)

yaw = deg((xu - xd)/LUD)

For programming the macromotors, also the

inverse transforms need to be specified:

inverse transforms

xu = xt

+ yaw*LUD/2

xd = xt

- yaw*LUD/2

yt

= yt

zu = zt -

rad(pitch)*LUD/2

zdr = zt +

rad(pitch)*LUD/2 - rad(roll)*LRF/2

zdf = zt +

rad(pitch)*LUD/2 + rad(roll)*LRF/2

The optical table dimensions are:

The trivial transformation for motor yt

was included for completeness. The auxiliary motor zd is useful for the

pinhole alignment (see section "Optical Bench"). The macromotor

definitions are contained in file dtable.mac

on ~/Macros/nondist.