ISO flanges

conform to the vacuum flange standards issued by the International

Standards Organization (ISO). They share the same underlying

principle as the QF (KF or NW) flange series in that two

smooth-faced sexless flanges clamp together with a sealing device

between them. Each flange face has a counter-bore into which fits a

metal Centering

Ring with an elastomeric O-ring around its outer diameter.

The centering ring has two roles: first to align the flanges; and

second to prevent the O-ring being pushed in by the external

atmospheric pressure when the joint is under

vacuum.

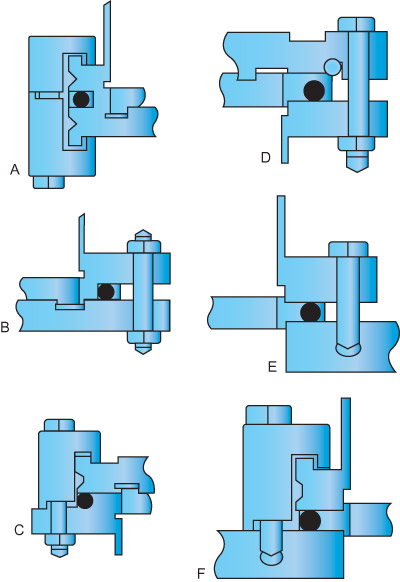

ISO

flanges have two clamping mechanisms holding the flanges together.

The first, called K-style, uses separate clamps hooked over the

outer edge of the mating flanges and spaced around the

circumference. The second, called F-style, uses conventional bolt

holes in the flange periphery. While an F-style flange comes as a

single, solid part complete with bolt holes, it is also available,

and more commonly used, in a three part structure in which a K-style

flange is adapted with a retaining ring and a bolt ring into the

F-style (see diagrams below). The multi-part flange has the obvious

advantage that it mates to either K-style or F-style simply by using

the appropriate pieces in the assembly. The single part F-style,

however, also has an important advantage, though a less obvious one.

It has more strength than the multi-part flange when used as a

structural element to support the weight of the vacuum

system. |