Mi double mirror, PhS photon shutter, D deflector, Diff diffractometer; source distances in m).

INDEX

ID10B is equipped with a horizontal fixed-exit diamond (111) double crystal monochromator which is tunable in the energy range from 8 keV to 13 keV. The experimental hutch contains a beam deflector and a multi-purpose eight-circle diffractometer. Special emphasis is given to surface scattering geometries in both the horizontal and the vertical plane.

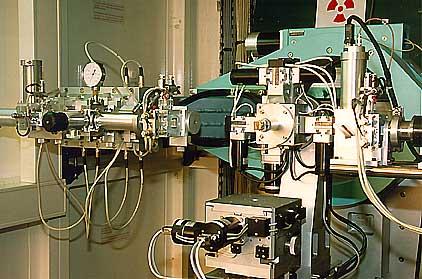

The experimental hutch is equipped with a deflector stage (D), mainly

for experiments on liquid surfaces. In order to follow the deflected beam,

the support of the diffractometer can be rotated around the deflector and

its height can be adjusted. The diffractometer (Diff) has a two-component

detector arm and a combined scattering stage for both horizontal and vertical

scattering geometries. The sample position on the diffractometer is at

41.7 m from the source.

| Fig. ID10B-1 | Schematic beamline layout (PS primary slits,

M1, M2 first and second monochromator vessel,

Mi double mirror, PhS photon shutter, D deflector, Diff diffractometer; source distances in m). |

|---|---|

Independent operation of ID10A and ID10B is guaranteed by two U42 undulators in the ID10 common front-end which can be operated simultaneously. Depending on the energy requirements, three modes of operation are possible:

The available energy range is given by the exit angle of the beryllium window (25° to 46°) of the first monochromator and the matching range of the translation stage of the second diamond(111) Bragg crystal. The second crystal is mounted on a high-resolution goniometer with the usual two rotations and two additional translations. The second monochromator vessel is operated under helium atmosphere, whereas the first monochromator in the white beam is operated in ultra-high vacuum.

A ultra-high vacuum chamber houses both mirrors. Each mirror is actuated via bellows by three motorized high-precision jacks forming a kinematic mount. For controlling and aligning the mirrors the displacements of the jacks are converted into incident angle, sideways tilt, and height for both mirrors. The whole mirror assembly can be shifted sideways to choose the required strip material. At the end of the mirror chamber the beam position can be determined with a wire monitor.

In the standard geometry, the first mirror deflects the beam up and

the second mirror reflects the beam back horizontally. Small downward deflections

of the x-ray beam up to 2.5 mrad for liquid scattering experiments can

be obtained by tilting the second mirror accordingly.

Another deflector option is the use of the Troika II horizontal multilayer bender. The elliptically-bent graded multilayer focuses the full width of the horizontal beam profile of about 1 mm into 25 mm (40:1 demagnification of the source), while the 0.3 mm height of the beam is conserved. The horizontal beam divergence will be on the order of 1 mrad in this case. This option is very useful for grazing-incidence diffraction experiments in the vertical scattering geometry that require very high flux at moderate resolution perpendicular to the sample surface. Furthermore the performance of the beamline in 16 bunch mode and even in single bunch mode gets strongly enhanced and the reduced available intensity in these special operation modes can be compensated for.

In order to follow the deflected beam, the diffractometer is supported

by a table which can be moved on airpads around the deflector axis from

0° to 30°. The table height can be adjusted from -130 mm to +70

mm, accordingly. The incident beam flight path comprises an aluminium attenuator

wheel, a second optional mirror, a set of motorized secondary slits defining

the beam profile at the sample, and a Kapton x-ray monitor. Other optional

devices are a filter inserter box and motorized guard slits or collimating

slits.

|

|

|---|---|

| Fig. ID10B-2 | Schematic side view of the Troïka II instrumentation in the experimental hutch.. |

|

|

|---|---|

| Fig. ID10B-3 | ID10B diffractometer - axis names in sixc and id10b configurations. The main slits are also shown. . |

The sample stages were designed to maximize the available volume for

sample environments. The horizontal sample stage consists of a horizontal

turn table, a height translation and crossed arcs. In combination with

the deflector this stage has a six-circle or z-axis configuration. The

horizontal stage is primarily used for scattering from liquid interfaces.

Furthermore heavy sample environments up to 100 kg can be supported without

counterweighting. A hemispherical volume of 450 mm diameter is available

for sample environments. The sample position is 170 mm from the top of

the crossed arcs. Optionally a xy-translation stage can be added on top

of the arcs. The horizontal sample stage has been used to support the beamline

Langmuir trough developed in collaboration with the Saclay-Group or a portable

UHV chamber.

|

|

|---|---|

| Fig. ID10B-4 | Sample stages of the ID10B diffractometer. View in beam direction facing downstream. |

The vertical sample stage comprises a vertical turntable and a long z translation which permits to position the sample surface precisely into the beam, or otherwise remove this stage from the scattering position, if necessary. This stage is controlled by a 2+2 diffractometer code (two detector axes and two sample axes). Additionally the sample goniometer has crossed arcs to line up the surface normal parallel to the vertical scattering rotation axes. x and y translations permit to choose a good spot on the sample. The sample position is at 110 mm from the top plate of the crossed arcs. The vertical scattering stage can be used for small sample environments of less than 2 kg and 250 mm diameter, i.e. helium-filled cells or electrochemical cells.

|

|

|---|---|

| Fig. ID10B-5 | ID10B 8-circle diffractometer with horizontal and vertical sample stages and standard detector arm. |

The detector arm has three possible configurations: The default configuration comprises an MicroControle X48 optical bench, motorized front slits, variable length flight path with Kapton windows and motorized detector slits. Either a scintillation detector, a Kapton detector or a 50 mm linear detector (MBraun) can be used with this set-up. Alternatively the X48 bench can be equipped with a 150 mm Soller collimator of 1.4 mrad resolution and a 150 mm linear gas detector (Gabriel, EMBL) for the horizontal scattering configuration.

The second configuration consists of an analyzer stage. In horizontal scattering geometry a 150 mm Si(111) analyzer crystal can be combined with a 150 mm linear gas detector. In vertical scattering geometry various 50 mm analyzer crystals (Si(111), Ge(111)) can be combined with a 50 mm linear gas detector.

The third configuration of the detector arm provides a mount for a MicroControle

X95 profile which can be used for equipment that was originally designed

for the Troïka I station.

Basic data evaluation can be performed on a second terminal of the work station or on the beamline PC. Data from the workstation can be directly accessed from the PC. Some basic software for data analysis and commercial software packages are available on the workstation and on the PC.

A Brief ID10B Beamline History

ID10B exploits mostly ESRF in-house designs:

| diamond beamsplitter | Gerhard Gruebel and Andreas Freund |

| UHV monochromator | Gerhard Gruebel and Muriel Mattenet |

| fixed exit monochromator | Gerhard Gruebel, Detlef Smilgies, and Keith Martel |

| deflector | Detlef Smilgies and Keith Martel |

| diffractometer | Detlef Smilgies and HUBER Diffraktionstechnik |

| main mirrors | Detlef Smilgies and Muriel Mattenet |

| analyzer stage | Detlef Smilgies, Nathalie Boudet, and Muriel Mattenet |

| multilayer bender | ESRF Optics Group |

| beamline Langmuir trough | in collaboration with Alan Braslau and Jean Daillant (CEA Saclay) |

Assembly and wiring of the beamline components was done expertly within the Troika Group by Patrick Feder and Henri Gleyzolle with support from ESRF Technical Services, the ESRF Engineering Office (Muriel Mattenet, Keith Martel, Gilles Retout) and the ESRF Computer Group (Joerg Klora). High quality monochromator and analyzer crystals as well as the graded multilayer were provided by the ESRF Optics Group. The main mirrors were manufactured by Optiques Fichou.

Troika II started User Mode in April 1998. Scientific beamline staff

consisted of Detlef Smilgies (3/1996-5/2000), Nathalie Boudet (11/1997-12/1998),

Bernd Struth (7/1998 to present) and Oleg Konovalov (3/1999 to present).

The installation and commissioning of the main mirrors in sommer 1999 marked

the end of the basic beamline construction. A nice account of scientific

work performed at ID10B was presented in various contributions at the ESRF

User Meeting Satellite Workshop "Surface Science 2000: Self-Organization

at Interfaces and in Thin Films" organized by Detlef Smilgies, Jean-Francois

Legrand (CEA Grenoble), Salvador Ferrer (ESRF), and Roberto Felici (INFM).

In spring 2000 I accepted an offer from Cornell University as staff scientist for the G-line project and Oleg Konovalov succeeded me as responsible beamline scientist for ID10B in May 2000. For the most recent, detailed description of the ID10B beamline see the ESRF Beamline Handbook.

Detlef Smilgies, July 2001