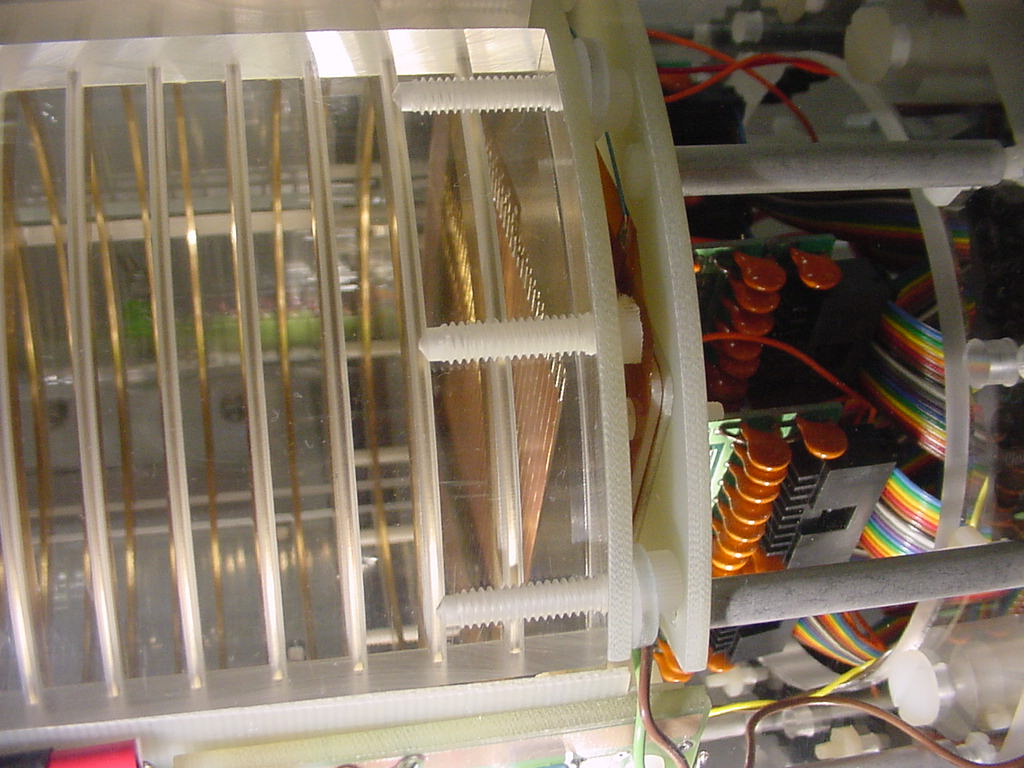

A "Stress Relief Test Plate" has been measured with an applied load. As shown in the photos, weights were applied at the mullions. The total load is 5kg (11 pounds). The total area of the openings (exluding the surrounding frame)(50cm x 34cm) is 280 square inches. Atmospheric pressure is 14.7psi. Thus, the pressure due to the weights is 11/(280*14.7)= 2.6 millibar.

The center of the longest span mullion deflected by 7 microns with an applied load of 2.6 millibar. Tranverse motion was less than 3 microns.

"Stress Relief Test Plates" have gone through the first cycle: machined to 0.75mm oversize, measured, stress relief, measured. Two plate were rapididly cooled to liquid nitrogen; two plates were heated to 325F (163C); two plates had no thermal process. The largest distortions after the first machining were bowing of the mullions by as much as 0.15mm. The plates moved by less than 0.05mm during the stress relief process.

The first two photos shows a plate during measurment in the CMM.

The figure shows the results, in the z-view, of one of the measurements. (Use the pdf version if you actually want to look at the numbers.) Units are 0.001inch (0.025mm). This plate is bowed up at the indicated locations.

The last photo shows a plate during the second cut - to 0.25mm oversize.

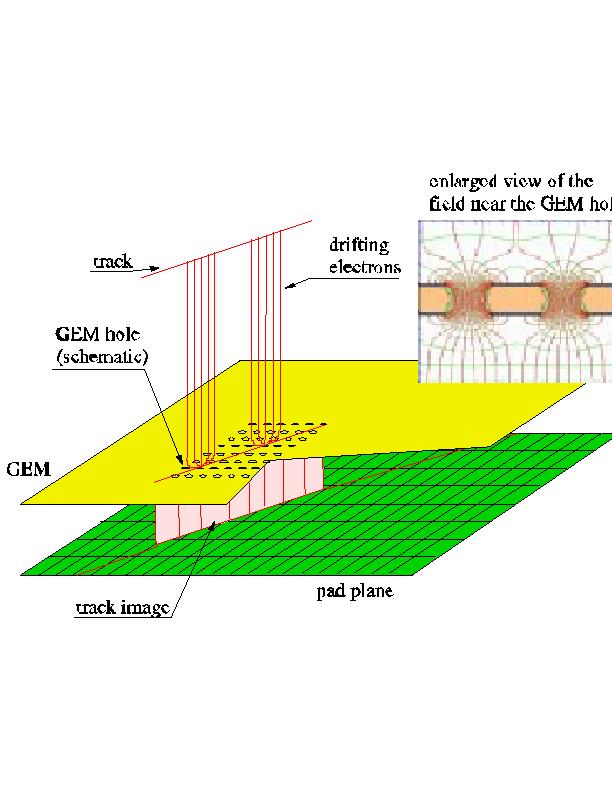

PRESENTATIONS

PRESENTATIONS

(purdue)

(purdue)