SRF News: 2013

Cornell Nb3Sn Program Produces Cavity that Exceeds Previous Limitation (07/12)

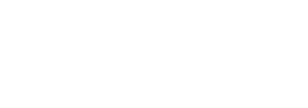

Four years ago, Cornell began pioneering new R&D on SRF cavities fabricated with Nb3Sn. Matthias Liepe and graduate student Sam Posen developed facilities to reproducibly fabricate Nb3Sn coatings with excellent superconducting properties on standard niobium cavities. The second such cavity fabricated at Cornell was tested in July, and with a Q of 1010 at an accelerating field of 12 MV/m and a temperature of 4.2 K, it far outperforms previous cavities of its type, which were produced by other labs in the 1980s. At the time, cavities consistently showed a degradation in Q above an accelerating gradient of approximately 5 MV/m, and it wasn't clear if the degradation was due to a fundamental limitation mechanism of the material or if it could be cured. This Q vs E curve is the first to show that the degradation is not fundamental.

This experiment is a big breakthrough for Cornell's Nb3Sn program, and it shows the vast potential of the material for SRF applications. The 4.2K Q of 1010 is approximately 20 times that of a standard niobium cavity, leading to much smaller cryogenic requirements, and opening up the possibility for exciting new applications. With a maximum accelerating field above 10 MV/m, this is the first Nb3Sn cavity that it would make sense to put into an accelerator; if this performance can be achieved above 15 MV/m, Nb3Sn would be very attractive for ERL applications, and could significantly reduce the cost of the proposed Cornell ERL.

Sam is beginning his 5th year of PhD studies in the SRF group. He is assisted this summer by SRCCS student Fiona Wohlfarth.

Four years ago, Cornell began pioneering new R&D on SRF cavities fabricated with Nb3Sn. Matthias Liepe and graduate student Sam Posen developed facilities to reproducibly fabricate Nb3Sn coatings with excellent superconducting properties on standard niobium cavities. The second such cavity fabricated at Cornell was tested in July, and with a Q of 1010 at an accelerating field of 12 MV/m and a temperature of 4.2 K, it far outperforms previous cavities of its type, which were produced by other labs in the 1980s. At the time, cavities consistently showed a degradation in Q above an accelerating gradient of approximately 5 MV/m, and it wasn't clear if the degradation was due to a fundamental limitation mechanism of the material or if it could be cured. This Q vs E curve is the first to show that the degradation is not fundamental.

This experiment is a big breakthrough for Cornell's Nb3Sn program, and it shows the vast potential of the material for SRF applications. The 4.2K Q of 1010 is approximately 20 times that of a standard niobium cavity, leading to much smaller cryogenic requirements, and opening up the possibility for exciting new applications. With a maximum accelerating field above 10 MV/m, this is the first Nb3Sn cavity that it would make sense to put into an accelerator; if this performance can be achieved above 15 MV/m, Nb3Sn would be very attractive for ERL applications, and could significantly reduce the cost of the proposed Cornell ERL.

Sam is beginning his 5th year of PhD studies in the SRF group. He is assisted this summer by SRCCS student Fiona Wohlfarth.

World-record Q0 for a multi-cell cavity of the Cornell ERL (06/20)

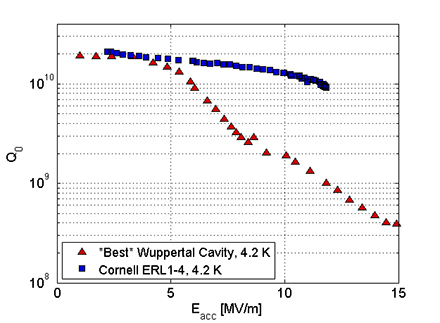

Left: The measured quality factor Q0 of the prototype ERL cavity as function of accelerating field. The design goal of 2x1010 at accelerating fields of 16MV/m was exceeded by almost 2, 3, and 5 at temperatures shown. Right: The Horizontal Test Cryostat that is used at Cornell to test the superconducting accelerating cavity in its full accelerator environment with beam pipes, power couplers, and Higher Order Mode absorbers.